About HUAYI Mould Co., Ltd.

Extrusion Tooling & Die Head (Mould) Solutions for PVC, UPVC, PE, PP, PS, PC, ABS, WPC — and more

HUAYI Mould is a China-based manufacturer of extrusion tooling and die heads (moulds) for plastic profile and board lines. We design, machine, polish, assemble, and test turnkey tooling systems that raise throughput, stabilize melt flow, and deliver consistent surface quality — across PVC, UPVC, PE, PP, PS, PC, ABS, WPC, and more.

What we deliver: faster start-ups, fewer changeovers, longer service life, and responsive technical support for global B2B buyers.

What We Do

- Extrusion Tooling / Die Heads (Moulds) for profiles, panels, decking, fencing, cladding, and boards

- Calibration & Cooling (vacuum calibrators, dual-circulation water cooling, water tanks)

- Flow-Channel Engineering (balanced runners, mirror finishing, chrome plating)

- Optimization & Upgrades (retrofit existing lines, speed & yield improvements)

- Commissioning & Support (debugging, remote/onsite assistance, spare parts)

Materials supported: PVC, UPVC, PE, PP, PS, PC, ABS, WPC (wood-plastic composites), and custom blends.

Main Entrance of HUAYI Mould Co., Ltd. — The modern headquarters and manufacturing facility located in Hubei, China, representing HUAYI’s commitment to quality, innovation, and global service in extrusion tooling and die head manufacturing.

Why Manufacturers Choose HUAYI

- Proven B2B track record: 100+ long-term customers across Vietnam, India, Turkey, Nigeria, Europe & the Americas

- End-to-end control: In-house CNC machining, wire cutting, spark erosion, heat treatment, mirror polishing

- Durability by design: Tool steels 3Cr17NiMo / DIN 1.2316 with hard chrome plating and special treatments

- Custom-built for your line: Width, thickness, pattern, and output tailored to your extruder, haul-off, and downstream

- Fast lead time: Typical ~ 15 working days with pre-shipment testing and acceptance report

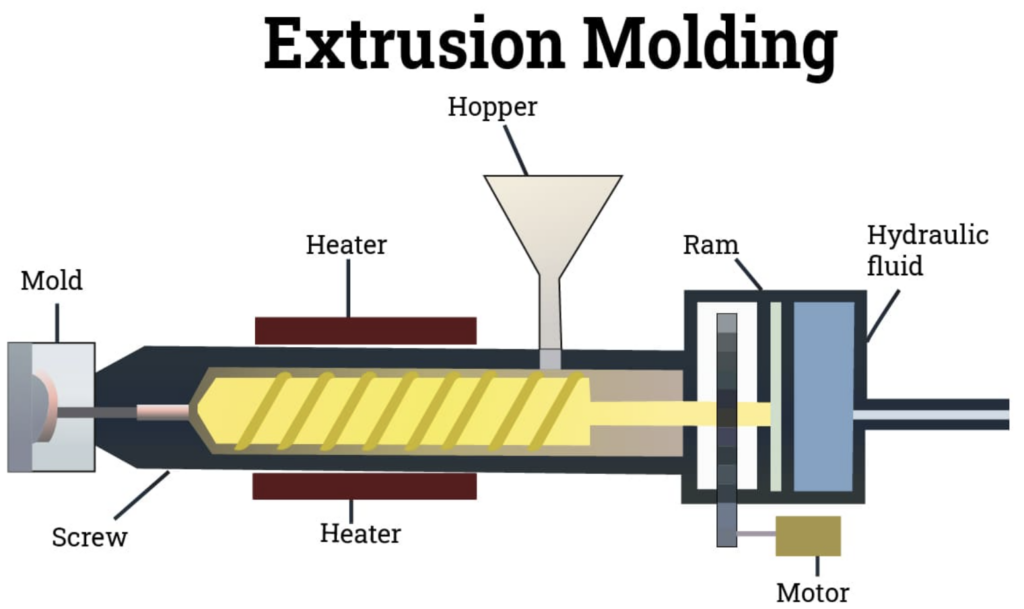

How We Build Better Tooling

- Application Study — substrate, formulation, target output, tolerance, surface spec

- Flow Simulation — balanced channels, pressure drop, shear rate, temperature control

- Precision Machining — CNC + EDM + mirror finishing for low friction and stable flow

- Cooling Strategy — dual-circulation water cooling + vacuum calibration for quick shaping

- Testing & Handoff — dry-run checks, documentation, spare sets, remote/onsite startup support

HUAYI Mould CNC machining workshop in Hubei, China – extrusion tooling and die head manufacturer

Quality & Reliability

- Mirror-polished channels for smooth melt and high gloss

- Tight tolerance machining; pinned plates for quick re-assembly

- Repairable modules and standard heater/thermocouple layouts

- Corrosion & wear resistance via surface treatments and steel selection

- Full inspection before dispatch; packing in export-grade polywood cases

Design & Engineering Office at HUAYI Mould — Our skilled engineers work collaboratively on extrusion tooling design and optimization, ensuring each die head and mould delivers precision, efficiency, and long-term reliability.

HUAYI Mould manufacturing workshop in Hubei, China – CNC machining and extrusion tooling production line

Industries & Use Cases

- WPC (PE) decking & flooring, outdoor fencing, exterior cladding

- PVC / UPVC panels, ceiling boards, profiles, windows/doors components

- PE / PP utility and industrial profiles; ABS / PC specialty sections

Customized width & geometry: We build to your drawing or co-develop the profile for faster qualification.

Customer-Centric B2B Service

- OEM/ODM cooperation, NDAs on request

- Multilingual sales & technical support

- Replacement kits and upgrade programs for legacy tooling

- Transparent milestones, photo/video updates during build

HUAYI Mould conference room – team meeting and product development discussions at extrusion tooling manufacturer in China

Company Snapshot

- Team: 100+ staff | 10 R&D engineers | 10 senior testing specialists

- Equipment: 80+ precision machines (CNC, EDM, polishing lines, inspection)

- Capacity: ~1,000 sets/year (moulds/tooling packages)

Call to Action

Tell us your profile and target output — we’ll engineer the tooling.

- 📧 Email: [email protected] | [email protected]

- 📱 WhatsApp: +86 133 7780 8937 (chat now)

- 🌐 Web: www.MouldHUAYI.com

- 🏭 Address: No. 48, Baiwen Industrial Park, Hubei Province, 435000, China

Follow us:

LinkedIn | Facebook | YouTube | X / Twitter

FAQs (B2B Buyer Focus)

Q1. Can you match our existing line (extruder brand/output)?

Yes — we design for your screw/barrel, die face pressure/temperature, haul-off, and downstream.

Q2. What steels and finishes do you use?

3Cr17NiMo / DIN 1.2316 with hard chrome plating; mirror-polished channels to reduce shear and fouling.

Q3. Do you support WPC (PE) decking with embossing?

Yes — we support pattern design, surface texturing, and sanding options.

Q4. Typical lead time?

Around 15 working days after specs are locked.

Q5. Do you provide debugging/commissioning?

Yes — remote or onsite; we also offer optimization for speed/yield.

Choose HUAYl Mould for precision, innovation, and a commitment to elevating your molding experience. Your success is our priority.

Global Excellence

HUAYl Mould, recognized by the China Plastic Products Association, is a leading force in precision molding. With a dedicated team of over 100 professionals, including 10 engineers and 10 testing specialists, we contribute significantly to industry advancements on a global scale.

Cutting-Edge Technology

Leveraging advanced techniques such as CNC machining, wire cutting, spark drilling, and a state-of-the-art production line, we produce nearly 1000 sets of molds annually. Our commitment to innovation aligns with industry trends, ensuring the delivery of top-quality products to clients worldwide.

Customer-Centric Partnership

At HUAYl Mould, customer satisfaction is paramount. With a global presence spanning the United States, Australia, India, and more, we’ve earned the trust of nearly 100 customers. Our focus on quality, timely delivery, and dedicated service makes us the preferred choice for those seeking precision, innovation, and a reliable molding partner.

“Innovation in Mold“

Winner

“Global Industry Leadership“

Winner

“Customer Satisfaction “

Winner