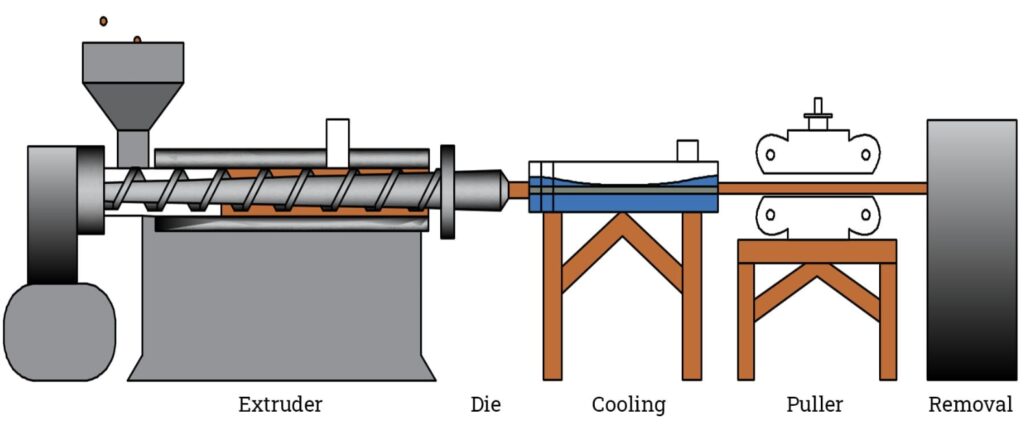

In recent years, the PVC extrusion mold industry and WPC extrusion mold industry have witnessed remarkable progress in technological innovation and the expansive scope of product applications. This article unveils the current state of these two industries and the broad range of applications, providing key insights and inviting you to explore the professional services offered by Huayi Mould.

PVC Extrusion Mold Industry: Pioneering Breakthrough Innovations

The PVC extrusion mold industry is advancing at an exciting pace, integrating innovation into every aspect of product design and manufacturing. From building materials to electrical circuits, PVC molds find wide applications, with high weather resistance and superior chemical stability making them the preferred choice across various sectors.

The adoption of innovative technologies such as advanced CNC machining, precision wire cutting, and efficient mold production lines has not only enhanced the production efficiency of PVC extrusion molds but also met the market’s increasing demands for quality and sustainability.

WPC Extrusion Mold Industry: The Perfect Fusion of Nature and Technology

The WPC (Wood-Plastic Composite) extrusion mold industry is leading the market with its outstanding performance and eco-friendly characteristics. The perfect combination of wood fibers and plastic makes WPC molds stand out in applications such as outdoor furniture, flooring, and railings. Their weather resistance and malleability not only ensure product durability but also align with the principles of sustainable development.

Huayi Mould employs cutting-edge technology and advanced material science to provide customized solutions for the WPC extrusion mold industry. We not only meet market demands but also exceed expectations, seamlessly integrating innovation and environmental consciousness.

Wide Range of Product Applications: Co-creating the Future

The extensive application areas of PVC and WPC extrusion molds include construction, furniture, transportation, electrical equipment, and more. Whether you are looking for innovative architectural elements or seeking sustainable, green furniture solutions, our mold services cater to your diverse needs.

Contact Us to Shape a Bright Future

In the world of extrusion molds, Huayi Mould has consistently led the tide of innovation and quality. If you are interested in our services or have any specific requirements, feel free to reach out to our customer service team. We are dedicated to providing customized solutions and co-creating a future that is both innovative and sustainable.

Contact Information: